Oil&Gas

Core Product Features

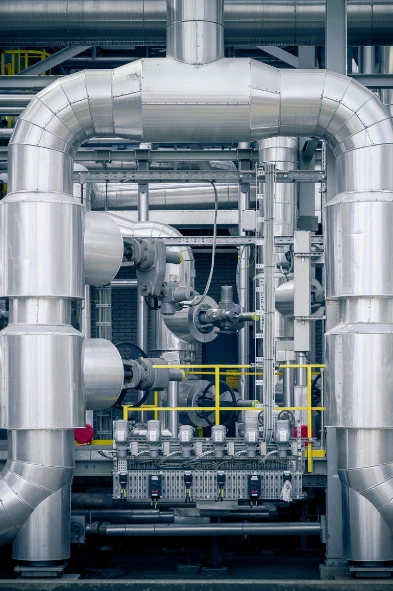

Long-Distance Pipeline Ball Valves | Pneumatic Control Valves | Electric Control Valves | High-Pressure Angle Control Valves

Key Applications & Case Studies

Emergency Shut-off and Regulation for Crude Oil & Natural Gas Pipelines

Reactor Feed Control for Refining Units (e.g., FCC, Hydrotreating)

High-Temperature and High-Pressure Steam Control

High-Pressure Differential Control for Wellhead Equipment

Core Features & Technical Advantages

Fire-Safe Design: Certified to API 607/6FA standards, it forms a metal-to-metal seal under fire conditions to prevent catastrophe escalation

Explosion-Proof Certification: Products are ATEX-certified for use in flammable and explosive environments

High Pressure﹠Sulfur Corrosion Resistance: Features high-pressure rated body and SSC-resistant materials, suitable for high-ΔP and H₂S-containing services

Emergency Pressure Relief: Automatically vents the valve body cavity during abnormal pressure buildup to improve system safety

Intelligent Control﹠Remote Monitoring:Supports HART, Profibus DP, Modbus protocols; integrates with DCS/PLC systems for remote monitoring and fault diagnostics.

Chemical Industry(Including Coal-to-Chemicals)

Core Product Features

Pneumatic Oxygen Control Valves | Bellows Seal Valves | High-Pressure Angle Control Valves | Corrosion-Resistant Butterfly Valves

Key Applications & Case Studies

Oxygen Control for Coal-to-Chemicals (CTC) Gasification Units

Control and Isolation of Highly Corrosive Media (e.g., Acetic Acid, Sulfuric Acid) in Polyvinyl Alcohol (PVA) and Purified Terephthalic Acid (PTA) Processes

High-Pressure Differential Control for Urea Systems

Hazardous Gas Management (O₂/Cl₂)

Core Features & Technical Advantages

Corrosion/Erosion Resistance: Offers austenitic stainless steel, Hastelloy, titanium and other special metals with surface treatments. Valve trim commonly uses Stellite alloy hardfacing (≥HRC 55-60) to enhance hardness and wear resistance.

High-Sealing Integrity: Utilizes PTFE-graphite composite packing and bellows seal structures to ensure zero leakage of highly toxic and hazardous media.

High Pressure Drop﹠Anti-Cavitation Design: Multi-stage throttling (e.g., in high-pressure angle valves) effectively distributes pressure drop, reducing cavitation and erosion to extend service life.

Degreasing Treatment: Valves for oxygen and other special media undergo degreasing to ensure safety.

Core Strengths&Technical Support

Core Product Features

Comprehensive Product Portfolio

Key Applications & Case Studies

Ensures operational continuity and efficiency, minimizes downtime losses, and meets stringent standards for safety, environmental compliance, and reliability across all sectors.

Core Features & Technical Advantages

Intelligent Positioning & Control:High-precision smart positioner delivers control accuracy of ±0.25% to ±0.5% with rapid response (pneumatic: <0.8s)

Stringent International Certifications: API 607/6D/6FA, ISO 15848-1, ATEX, SIL, meeting global project compliance requirements.

Localized Service & Rapid Response: Leveraging domestic bases and service centers for quick delivery of standard models (e.g., 72-hour), 24/7 technical support, with short mean-time-to-repair (electric: ≤4 hours; pneumatic: ≤6 hours)

Tel:

E:

Copyright:©2022-2026